Pressure sensitive adhesive is a type of adhesive that sticks when pressure is applied. It adheres on contact.

Pressure sensitive adhesives are widely used in various industries, from labels and tapes to medical applications and automotive products. They provide a convenient, clean, and efficient way to bond materials together without the need for additional equipment or heat. The versatility and ease of use make pressure sensitive adhesives a popular choice for many applications.

Understanding how pressure sensitive adhesives work and their benefits can help in selecting the right adhesive for specific needs. We will explore the characteristics, uses, and advantages of pressure sensitive adhesives.

The Science Behind Pressure Sensitive Adhesives

Pressure Sensitive Adhesive (PSA) is a type of adhesive that forms a bond when pressure is applied. The science behind these adhesives lies in their core ingredients. These adhesives are typically made up of a polymer base, tackifiers, and a solvent. The polymer base provides the adhesive properties, while the tackifiers enhance the adhesive’s ability to stick to surfaces. The solvent helps to keep the adhesive in a liquid state for easy application.

Viscosity and tack are two key factors that play a role in the effectiveness of pressure sensitive adhesives. Viscosity refers to the thickness or resistance to flow of the adhesive. A higher viscosity adhesive tends to have better gap-filling properties, while a lower viscosity adhesive may have better wetting characteristics. Tack, on the other hand, is the adhesive’s ability to stick to a surface with minimal pressure. The right balance of viscosity and tack is crucial for achieving optimal adhesive performance.

Varieties Of Pressure Sensitive Adhesives

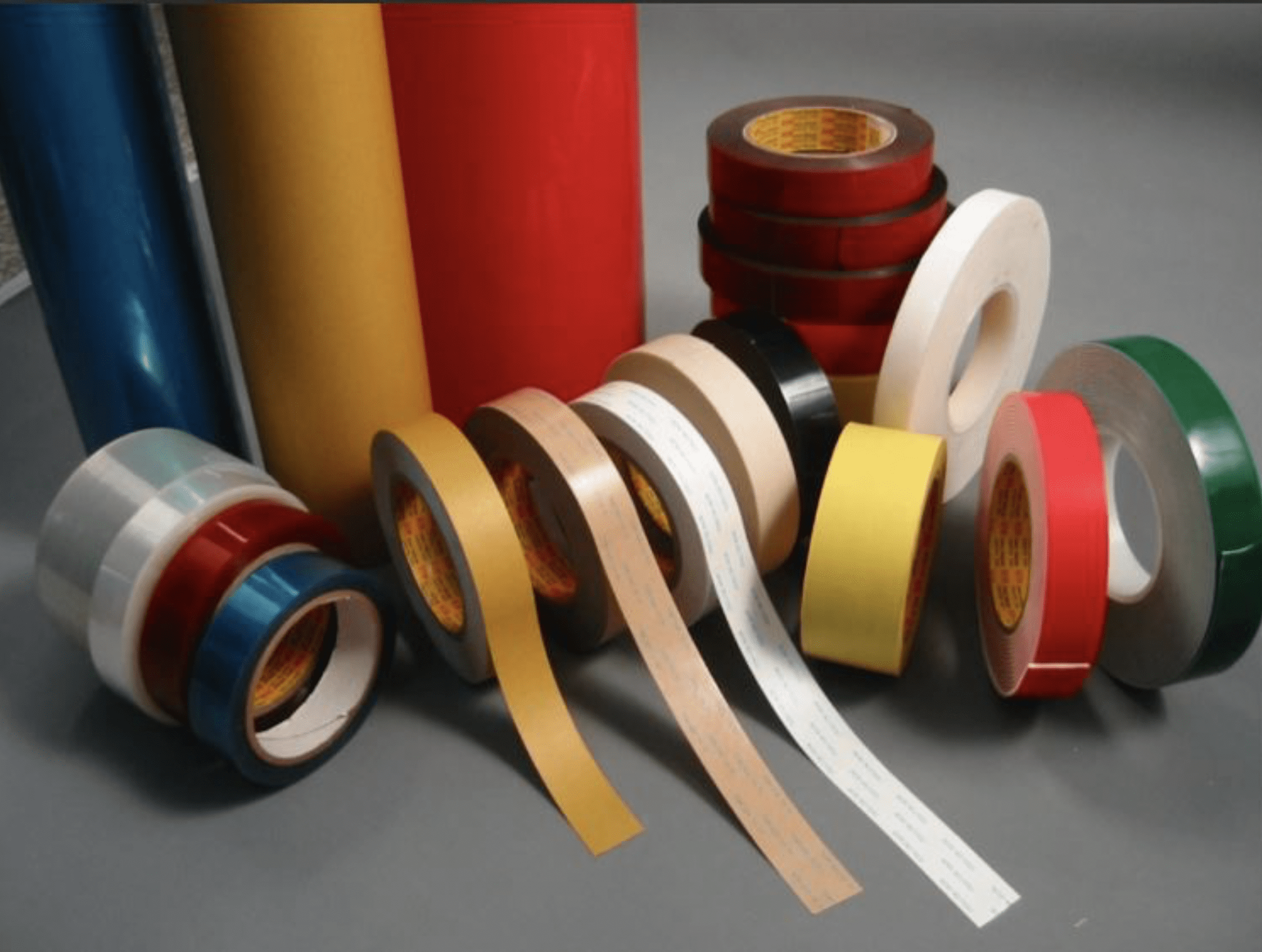

Pressure sensitive adhesives (PSAs) are versatile materials that offer strong bonding capabilities. Rubber-based adhesives are known for their flexibility and strong initial tack, making them ideal for applications such as labels and tapes. Acrylic-based adhesives are valued for their weather resistance and long-term durability, making them suitable for outdoor use and demanding environments. Silicone-based adhesives offer high-temperature resistance and excellent release properties, making them suitable for applications such as protective films and medical tapes.

How Pressure Sensitive Adhesives Work

Pressure sensitive adhesives (PSAs) are widely used in various industries due to their unique bonding properties. These adhesives work by creating an immediate bond when pressure is applied to the adhesive surface. The bonding process involves the following steps:

- Contact: When pressure is applied to the adhesive, it comes into contact with the substrate surface.

- Wetting: The adhesive spreads and wets the substrate surface, allowing for intimate contact.

- Diffusion: The adhesive molecules begin to diffuse into the substrate, creating a strong bond.

- Solidification: Over time, the adhesive solidifies, further enhancing the bond strength.

Several factors can affect the adhesion of PSAs, including surface energy, surface roughness, and substrate material. PSAs are designed to provide excellent adhesion to a wide range of surfaces, making them versatile and suitable for various applications.

Applications In Daily Life

Pressure sensitive adhesive (PSA) is a type of adhesive that forms a bond when pressure is applied to join the adhesive with the adherend. This versatile adhesive is widely used in various household applications, such as sticking notes, mounting photos, and securing carpets. In addition, pressure sensitive adhesives play a crucial role in industrial applications, including labels, tapes, and graphic films. The adhesive’s ability to form an instant bond without requiring any additional curing process makes it highly efficient for a wide range of applications.

Advantages Of Using Pressure Sensitive Adhesives

Pressure sensitive adhesives (PSAs) offer ease of use as they require no heat, water, or solvent for application. They provide versatility by adhering to a wide range of surfaces, including plastics, metals, and fabrics. Additionally, PSAs offer durability as they form a strong bond upon application, ensuring long-lasting adhesion. These adhesives are ideal for various applications, including labels, tapes, and graphic films.

Comparing Pressure Sensitive To Other Adhesive Types

Pressure sensitive adhesive is a type of adhesive that sticks when pressure is applied. Unlike other adhesives, it doesn’t require heat or water to bond. Its convenience and ease of use make it a popular choice for various applications.

| Pressure Sensitive Adhesive | Heat-Activated Adhesives | Water-Based Adhesives |

| Easy application with no need for heat or water. | Require heat to bond surfaces. | Use water as a carrier for the adhesive. |

| Immediate bonding upon contact with the surface. | Activation occurs upon heating. | Environmentally friendly and low odor. |

| Versatile and can be used on various surfaces. | Stronger bond due to the heat activation process. | Suitable for porous surfaces like paper and cardboard. |

Innovations In Pressure Sensitive Adhesive Technology

Pressure sensitive adhesive (PSA) technology is a type of adhesive that forms a bond when pressure is applied. It adheres to a variety of surfaces without the need for heat, water, or solvent activation. This innovative technology is widely used in labels, tapes, and other adhesive applications due to its ease of use and versatility.

| Pressure Sensitive Adhesive (PSA) is a type of adhesive that forms an instant bond when pressure is applied. |

| Smart Adhesives, a recent development, are designed to be environmentally friendly and sustainable. |

Challenges And Solutions In Pressure Sensitive Adhesive Manufacturing

Pressure sensitive adhesives (PSAs) are a type of adhesive that forms a bond when pressure is applied. They offer versatile solutions for various applications, from labels to tapes. However, challenges in manufacturing include ensuring consistent tackiness and adhesive performance across different substrates.

Developing precise formulations and optimizing production processes are key solutions to these challenges.

| Quality Control | Regulatory Compliance |

| Ensuring adhesive strength and durability through rigorous testing. | Adhering to industry standards and guidelines to meet legal requirements. |

| Regularly inspecting raw materials to maintain product consistency. | Implementing procedures to guarantee product safety and environmental stewardship. |

Frequently Asked Questions

What Is Pressure Sensitive Adhesive?

Pressure sensitive adhesive is a type of adhesive that sticks to a surface when light pressure is applied. It is commonly used in adhesive tapes, labels, and stickers. The adhesive remains tacky even after it has been dried and does not require heat or moisture to activate.

How Does Pressure Sensitive Adhesive Work?

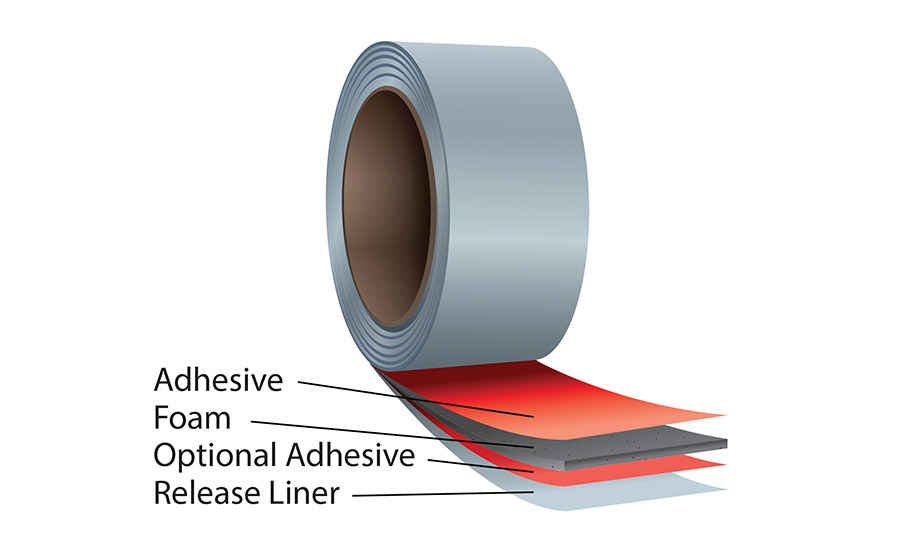

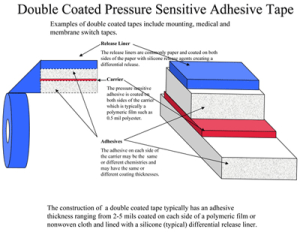

Pressure sensitive adhesive works by forming a bond between the adhesive and the surface it is applied to. The adhesive is coated onto a backing material, such as paper or plastic, and when pressure is applied, the adhesive bonds with the surface.

The bond is maintained by the adhesive’s ability to flow and conform to the surface.

What Are The Advantages Of Using Pressure Sensitive Adhesive?

Pressure sensitive adhesive offers several advantages over other types of adhesives. It is easy to use, requires no additional equipment, and does not create any mess or waste. It is also versatile and can be used on a wide range of surfaces.

Additionally, it can be removed easily without damaging the surface.

What Are Some Common Applications Of Pressure Sensitive Adhesive?

Pressure sensitive adhesive is used in a variety of applications, including labels, tapes, decals, and graphics. It is commonly used in the packaging industry for sealing and labeling boxes, as well as in the automotive industry for attaching emblems and trim.

It is also used in the medical industry for attaching electrodes and sensors to patients.

Conclusion

Pressure sensitive adhesive (PSA) is a versatile and widely used adhesive in various industries. Its unique properties, such as the ability to adhere to a variety of surfaces and the ease of application, make it a popular choice for many applications.

From labels and tapes to medical devices and automotive parts, PSA plays a crucial role in our daily lives. As technology advances, we can expect to see more innovative uses of PSA in the future.