J-B Weld Putty is better for filling gaps, while J-B Weld Epoxy is ideal for bonding surfaces. Choosing between J-B Weld Putty and J-B Weld Epoxy depends on the type of repair needed.

J-B Weld Putty works well for fixing gaps and holes, providing a strong and durable seal. On the other hand, J-B Weld Epoxy is great for bonding materials together permanently. Both products offer high-strength solutions for various DIY projects and repairs.

Understanding the differences between these two products can help you select the best option based on your specific repair needs. Let’s delve deeper into the characteristics and applications of J-B Weld Putty and Epoxy to determine which one suits your project requirements.

Introduction To Jb Weld Products

J-B Weld is a popular brand that offers a range of adhesive products, including putty and epoxy. The company was founded in 1969 and has since become a go-to for DIYers and professionals alike.

The history of J-B Weld dates back to the 1960s when two technicians working for the Apollo space program were tasked with finding a way to repair and bond metal components. They developed a unique formula that could withstand extreme temperatures and pressure, and J-B Weld was born.

J-B Weld products are known for their strength and durability, thanks in part to the key ingredients used in the formulas. These include epoxy resins, hardeners, and fillers that work together to create a strong and long-lasting bond.

| Jb Weld Putty | Epoxy |

|---|---|

| Great for filling gaps and holes | Perfect for bonding surfaces together |

| Can be sanded and painted over once dry | Dries clear and can be sanded and painted over |

| Can withstand temperatures up to 300°F | Can withstand temperatures up to 550°F |

Whether you’re working on a DIY project or need a reliable adhesive for professional use, J-B Weld products are a great choice. With their strong and durable formulas, you can trust that your repairs will last.

The Science Of Adhesives

Jb Weld Putty Vs Epoxy are two common types of adhesives used for various purposes. Adhesives work by creating a bond between two surfaces, providing strength and stability. The chemical composition of adhesives determines their properties and applications. Epoxy adhesives consist of resin and hardener, while J-B Weld Putty is a two-part epoxy putty. Other types of adhesives include cyanoacrylate, polyurethane, and silicone. Each type offers unique characteristics such as curing time, strength, and flexibility. Understanding the differences between these adhesives can help in choosing the right one for a specific application.

Jb Weld Putty At A Glance

JB Weld Putty and Epoxy are versatile adhesives that can be used for a variety of applications. JB Weld Putty is a two-part epoxy putty that is designed to repair and rebuild various surfaces. It is composed of a resin and a hardener that, when mixed together, create a strong and durable bond. The putty is resistant to heat, chemicals, and pressure, making it ideal for use in high-stress environments. JB Weld Putty can be used to repair metal, wood, plastic, glass, and more.

Epoxy, on the other hand, is a two-part adhesive that consists of a resin and a hardener. When mixed, the two components chemically bond to form a strong, rigid material. Epoxy is known for its excellent adhesion and resistance to chemicals, heat, and water. It is commonly used for bonding, sealing, and filling various materials, including metal, wood, plastic, and glass.

Both JB Weld Putty and Epoxy are ideal for use in applications that require a strong, durable bond. They can be used for automotive repairs, plumbing fixtures, household repairs, and more. When choosing between the two, consider the specific requirements of the project and the materials being bonded to select the most suitable adhesive.

Jb Weld Epoxy Overview

Jb Weld Putty and Epoxy are both versatile adhesives that offer strong bonding properties. When it comes to Jb Weld Epoxy, it is essential to understand the basics of epoxy adhesives.

Epoxy is a type of adhesive that consists of two components – resin and hardener. These components need to be mixed together in a specific ratio to activate the adhesive properties. Once mixed, the epoxy forms a strong bond that is resistant to heat, chemicals, and impacts.

Knowing when to use Jb Weld Epoxy is crucial for achieving optimal results. It is ideal for bonding various materials, including metal, wood, plastic, and ceramics. Whether you need to repair broken objects, fill gaps, or create durable bonds, Jb Weld Epoxy can provide the necessary strength and reliability.

With Jb Weld Epoxy, you can confidently tackle a wide range of projects, from automotive repairs to household fixes. It offers excellent adhesion and can withstand harsh environments, making it a go-to adhesive for many professionals and DIY enthusiasts.

So, whether you’re working on a small repair or a big project, consider using Jb Weld Epoxy for its reliable and long-lasting bonding capabilities.

Comparative Analysis

Strength and Durability

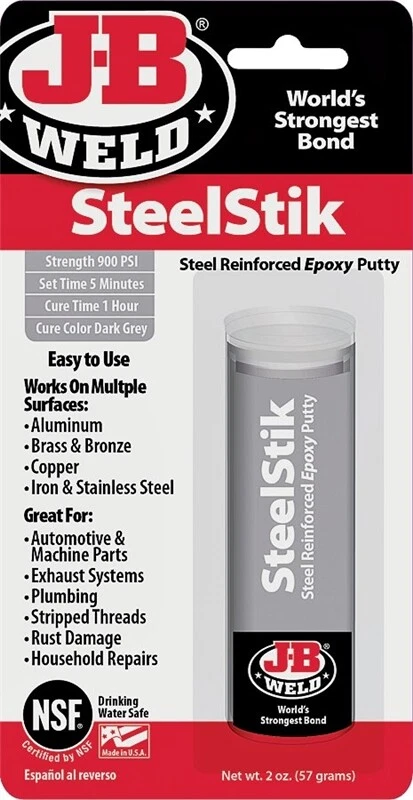

J-B Weld SteelStik is a hand-mixable, steel-reinforced, non-rusting epoxy putty that quickly repairs or rebuilds anything made of metal. It ensures a strong and durable bond that can withstand harsh conditions and heavy loads. On the other hand, J-B Weld Original Cold Weld Formula is a two-part epoxy system that provides strong, lasting repairs to metal and multiple surfaces. It delivers high strength and durability, making it suitable for a wide range of applications.

Setting Time and Curing Process

The J-B Weld SteelStik sets in 3-5 minutes and cures in 1 hour, while the J-B Weld Original Cold Weld Formula sets in 4-6 hours and fully cures in 15-24 hours. This variation in setting time and curing process allows users to select the product that best fits their specific project needs.

Ease Of Use And Application Techniques

Comparing Jb Weld Putty and Epoxy, both offer ease of use and application techniques. With simple instructions and user-friendly packaging, these products provide convenient solutions for various repairs and bonding projects. Whether you choose Jb Weld Putty or Epoxy, you can achieve reliable results effortlessly.

| Preparation and Application Tips |

| For J-B Weld Putty and Epoxy, clean and dry surfaces are crucial. |

| Smooth out the putty, blend it well, and apply evenly for best results. |

| Follow the recommended curing time for a strong bond. |

| Safety Measures |

| Wear protective gloves and ensure proper ventilation during application. |

| Avoid skin and eye contact; use in a well-ventilated area. |

Real-world Performance

When comparing J-B Weld putty and epoxy for real-world performance, consider their bonding strength, versatility, and application ease. J-B Weld putty offers quick fixes for a variety of materials, while epoxy provides a durable, long-lasting bond suitable for heavy-duty repairs.

Both products deliver reliable real-world performance for different applications.

| J-B Weld Putty | Epoxy |

| Quick fixes | Durable bond |

| High heat resistance | Waterproof seal |

| Great for metal | Best for plastics |

Versatility And Limitations

J-B Weld putty and epoxy offer versatility for various repair projects. The putty is ideal for filling gaps and holes, while the epoxy provides a strong bond for materials. However, both have limitations, such as longer curing times and temperature sensitivity.

Understanding their differences helps in choosing the right product for specific repair needs.

| Material Compatibility | Temperature and Environment Factors |

| J-B Weld Putty is ideal for bonding surfaces with varying materials. | Epoxy adhesive performs well under extreme temperatures and conditions. |

| Works effectively on metal, wood, plastic, and more. | Resistant to heat, cold, moisture, and chemicals. |

| Best for quick fixes and filling gaps. | Not recommended for applications exposed to excessive heat. |

Cost Considerations

When deciding between JB Weld putty and epoxy, it’s important to consider cost factors. While both options provide strong bonding capabilities, epoxy tends to be more expensive due to its longer curing time and higher overall strength. Therefore, JB Weld putty may be a more cost-effective solution for certain applications.

| Cost Considerations |

| When comparing Jb Weld Putty Vs Epoxy, the price difference is significant. |

| Jb Weld Putty tends to be more budget-friendly initially, but Epoxy offers better long-term value. |

| Consider your project needs and durability requirements for the most cost-effective choice. |

Final Thoughts

J-B Weld putty and epoxy are both reliable choices for various projects, but choosing the right one depends on your specific needs. While the putty is convenient for quick fixes and bonding, epoxy offers a stronger, more durable hold for demanding projects. Consider the complexity and size of your project, as well as the materials you are working with, before making your decision.

As for the future of J-B Weld innovations, the company continues to push the boundaries of adhesive technology, constantly striving to develop new and improved products to meet the ever-evolving needs of consumers and industries. With a commitment to quality and innovation, J-B Weld remains a pioneer in the adhesive market.

Frequently Asked Questions

What Is Jb Weld Putty?

Jb Weld Putty is a two-part epoxy that is designed to repair, bond, and fill various materials. It is a versatile adhesive that can be used on metal, wood, plastic, and more. The putty hardens in 4-6 hours and can withstand temperatures up to 300 degrees Fahrenheit.

What Is Epoxy?

Epoxy is a two-part adhesive that consists of a resin and a hardener. It is known for its strong bond and durability, making it a popular choice for repairs and construction. Epoxy can be used on a variety of surfaces, including metal, wood, and concrete.

What Is The Difference Between Jb Weld Putty And Epoxy?

Jb Weld Putty and Epoxy are both two-part adhesives that are designed to bond and repair materials. However, Jb Weld Putty is thicker and can be molded and shaped to fill gaps and cracks, while Epoxy is thinner and better for bonding surfaces together.

Jb Weld Putty also has a shorter curing time than Epoxy.

Can Jb Weld Putty And Epoxy Be Used Together?

Yes, Jb Weld Putty and Epoxy can be used together. Jb Weld Putty can be used to fill gaps and cracks, while Epoxy can be used to bond surfaces together. It is important to follow the instructions for both products and allow sufficient time for each to cure before using them together.

Conclusion

When comparing JB Weld Putty and Epoxy, both products have their strengths and weaknesses. JB Weld Putty is convenient for quick fixes and has a high heat resistance, while Epoxy offers a stronger and more permanent bond. Ultimately, the choice between the two depends on the specific project and requirements.

Consider the application, curing time, and desired durability to make an informed decision. Happy repairing!