J-B Weld is a strong epoxy adhesive known for its durability and bonding capabilities. It is highly reliable for various repair projects.

J-B Weld provides a secure and long-lasting bond that can withstand extreme conditions, making it a popular choice among DIYers and professionals alike. With its versatile application and robust formula, J-B Weld is a trusted solution for fixing metal, wood, plastic, and more.

Whether you’re repairing automotive parts, household items, or crafting projects, J-B Weld offers a dependable and effective bonding solution. Its strength and durability make it a go-to product for a wide range of bonding needs.

Introduction To Jb Weld

JB Weld is a two-part epoxy that has become a popular choice for bonding metals, plastics, and wood. The product was invented in the 1960s by Sam and Mary Bonham, who were trying to find a solution for repairing an aluminum casting.

What makes JB Weld unique is its ability to create a strong bond that can withstand high temperatures and pressure. The product is also resistant to chemicals and can be used in various applications.

| Origins of JB Weld | What makes JB Weld unique |

|---|---|

| The product was invented in the 1960s by Sam and Mary Bonham, who were trying to find a solution for repairing an aluminum casting. | JB Weld has the ability to create a strong bond that can withstand high temperatures and pressure. It is also resistant to chemicals and can be used in various applications. |

Overall, JB Weld has become a popular choice for those looking for a strong and reliable bonding solution. Its unique properties have made it a go-to product for both DIY enthusiasts and professionals alike.

The Science Behind Jb Weld

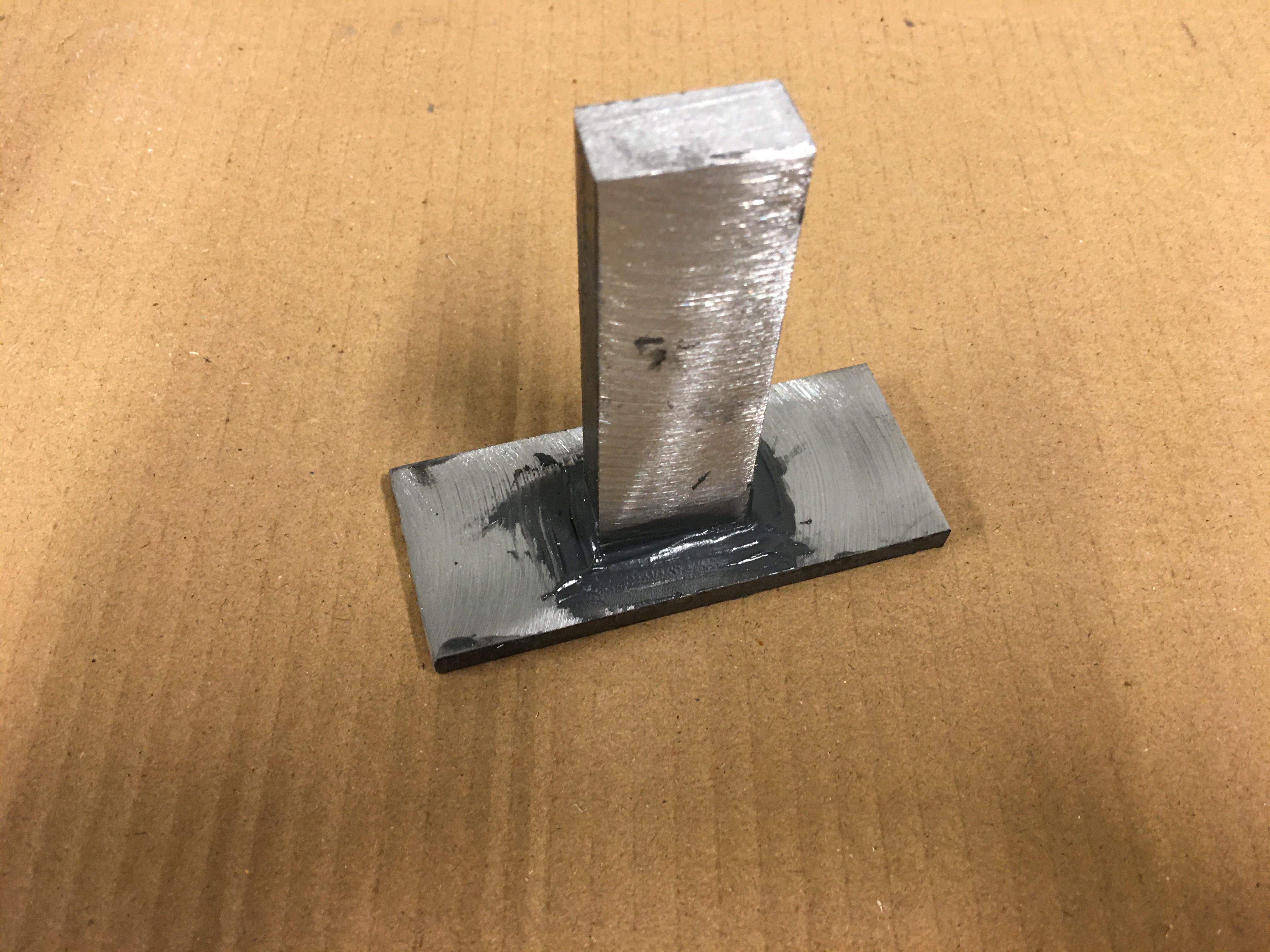

The strength of JB Weld comes from its key ingredients and the curing process. The two-part epoxy formula consists of resin and hardener, which work together to create a strong bond. The resin provides the adhesive properties, while the hardener initiates the curing process. When the two components are mixed, they undergo a chemical reaction that transforms them into a solid, durable bond. This curing process creates a bond that is resistant to heat, pressure, and chemicals, making JB Weld a reliable choice for various applications. Understanding the science behind JB Weld can help users appreciate its strength and reliability.

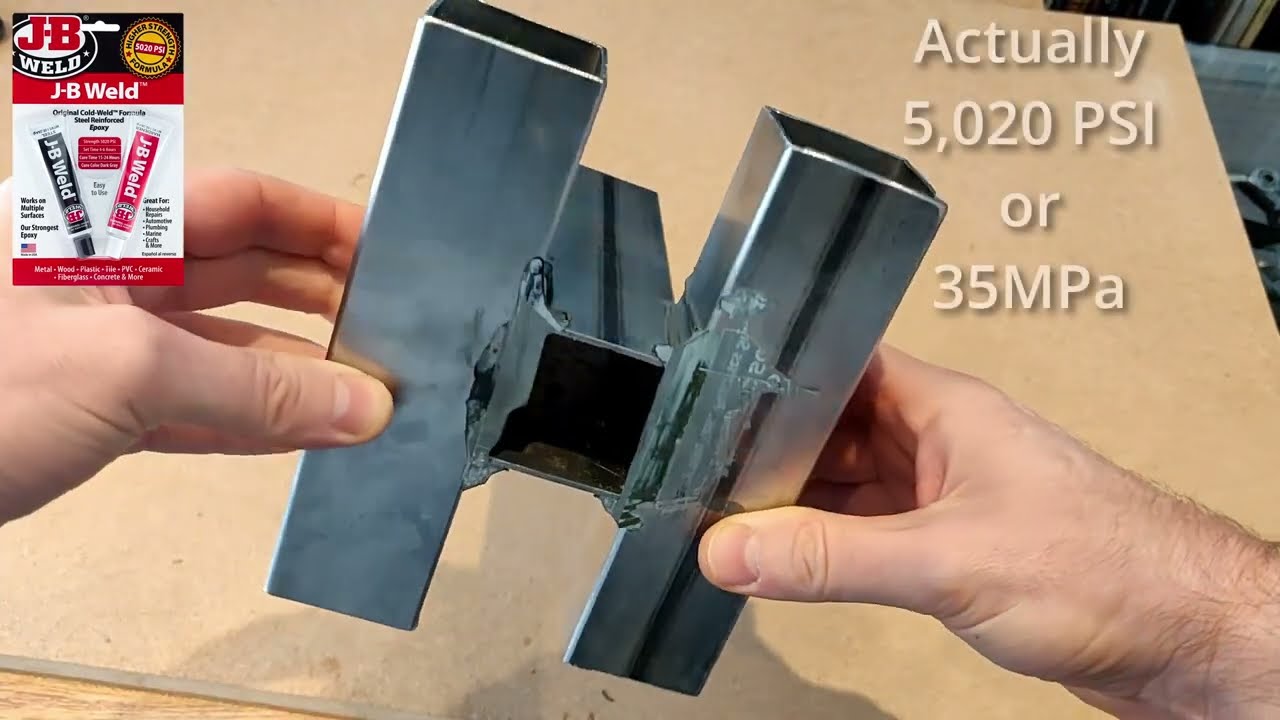

Comparing Strength: Jb Weld Vs. Other Adhesives

Compare the strength of JB Weld to other adhesives to see how it stands out. JB Weld offers exceptional bonding power for durable and long-lasting repairs. Its robust strength makes it a top choice for various bonding needs.

Comparing Strength: JB Weld vs. Other Adhesives JB Weld is renowned for its exceptional strength and durability, making it a popular choice for various bonding applications. When it comes to benchmarking against super glue, JB Weld emerges as the clear winner. Unlike super glue, which is known for its quick but temporary bonding, JB Weld provides a long-lasting and permanent solution. With its superior strength, JB Weld can withstand extreme conditions and heavy loads, making it ideal for structural repairs. In addition to comparing strength with super glue, it’s also essential to evaluate JB Weld against epoxy. Both JB Weld and epoxy offer strong bonding capabilities, but JB Weld stands out due to its versatility and ease of use. While epoxy requires precise mixing and can be messy, JB Weld simplifies the process with its two-part formula that ensures a proper blend every time. Moreover, JB Weld is resistant to chemicals, heat, and impact, making it a reliable choice in various industries and applications. In conclusion, when it comes to strength and durability, JB Weld outperforms other adhesives such as super glue and epoxy. Its exceptional bonding capabilities, versatility, and resistance to harsh conditions make it a go-to option for all your bonding needs.Real-world Applications

When it comes to automotive repairs, JB Weld is a popular choice for fixing cracked engine blocks, exhaust manifolds, and even metal engine parts. Its high heat resistance and strong bond make it ideal for withstanding the extreme temperatures and pressures in a car’s engine. Moreover, for household fixes and DIY projects, JB Weld can be used to repair metal, wood, plastic, and more. Whether it’s patching up a leaky pipe, fixing a broken tool, or securing a loose hinge, JB Weld provides a reliable and durable solution. Additionally, its versatility and ease of use make it a go-to product for a wide range of repair and maintenance tasks around the home and garage.

Temperature And Jb Weld

J-B Weld is a high-strength epoxy adhesive that can withstand a wide range of temperatures. It is heat resistant up to 550°F (287°C), making it suitable for a variety of applications, including automotive repairs and industrial uses. This makes J-B Weld a reliable choice for bonding and repairing tasks in high-temperature environments.

| Temperature and JB Weld |

| Effects of high temperatures on its bond |

| JB Weld is known for its resilience. Even at high temperatures, it maintains its strong bond. When exposed to extreme heat, it doesn’t weaken, ensuring reliable performance. Moreover, in cold weather, JB Weld’s effectiveness is not compromised. It remains dependable even in low temperatures, making it a versatile choice for various applications. |

Limitations And Considerations

J-B Weld is a strong epoxy adhesive, but it does have limitations and considerations. It may not be suitable for high-temperature applications or for use on flexible materials. Additionally, surface preparation is crucial for optimal bonding strength.

| J-B Weld is versatile for various repairs, but not recommended for high-heat situations. |

| Avoid using it on flexible parts or areas exposed to constant vibration. |

| Surface must be cleaned thoroughly for optimal adhesion and long-lasting bond. |

User Experiences And Testimonials

J-B Weld is known for its strong adhesive properties, providing users with reliable results for various applications. Customers have praised its durability and effectiveness in their testimonials, making it a trusted choice for bonding different materials together.

|

Future Of Jb Weld

|

JB Weld continues to innovate in adhesive technology, expanding its product line. The company’s commitment to quality and durability has solidified its reputation as a leader in the industry. With advancements in bonding materials, JB Weld offers solutions for various applications. |

Frequently Asked Questions

How Strong Is J-b Weld?

J-B Weld is incredibly strong and can withstand up to 3960 PSI of pressure. It is a two-part epoxy that sets in 4-6 hours and can fully cure in 15-24 hours.

What Materials Can J-b Weld Bond With?

J-B Weld can bond with a variety of materials, including metal, wood, plastic, ceramic, fiberglass, and more. It can even bond dissimilar materials together.

Is J-b Weld Heat Resistant?

Yes, J-B Weld is heat resistant and can withstand temperatures up to 550°F (287°C) once fully cured. This makes it ideal for use in high-temperature environments such as engines and exhaust systems.

Can J-b Weld Be Used On Wet Surfaces?

Yes, J-B Weld can be used on wet surfaces. However, it is recommended to remove as much water as possible and dry the surface before applying the epoxy for optimal bonding strength.

Conclusion

The strength of Jb Weld is undeniable. Its exceptional bonding properties make it a reliable choice for various applications. Whether you need to repair metal, wood, or plastic, Jb Weld provides a durable and long-lasting solution. Its versatility and easy application make it a popular choice among DIY enthusiasts and professionals alike.

So, when it comes to strong and reliable bonding, Jb Weld is a go-to option.