Gaffer tape is cloth-backed, leaves no residue, and is ideal for temporary use. Electrical tape is insulating and suitable for electrical work.

When choosing between gaffer tape and electrical tape, it’s essential to understand their unique qualities and applications. Both tapes have distinct features that make them valuable tools in various situations. Whether you need to secure cables in a performance setting or insulate electrical connections, selecting the right tape can make a significant difference in the outcome of your project.

Let’s delve deeper into the characteristics and uses of gaffer tape and electrical tape to help you make an informed decision based on your specific needs and requirements.

Introduction To Gaffer Tape And Electrical Tape

Gaffer tape is versatile for temporary fixes, while electrical tape is ideal for insulation and wire management. Each tape has distinct uses based on durability and adhesive strength. Understanding their differences helps in selecting the right tape for specific applications.

| Characteristic | Gaffer Tape | Electrical Tape |

|---|---|---|

| Origin | Originally used in the entertainment industry for stage set-ups and lighting | Developed specifically for electrical applications |

| Basic Uses | Securing cables and cords, holding down equipment, marking stages and floors | Insulating electrical wires, bundling cords, repairing damaged cables |

| Adhesive | Non-residue adhesive that can be easily removed without leaving any residue | Strong adhesive that forms a permanent bond with the surface |

| Water Resistance | Water-resistant but not waterproof | Waterproof and can be used for outdoor applications |

| Temperature Resistance | Can be used in a wide range of temperatures | Can withstand high temperatures and is flame retardant |

Composition And Material Differences

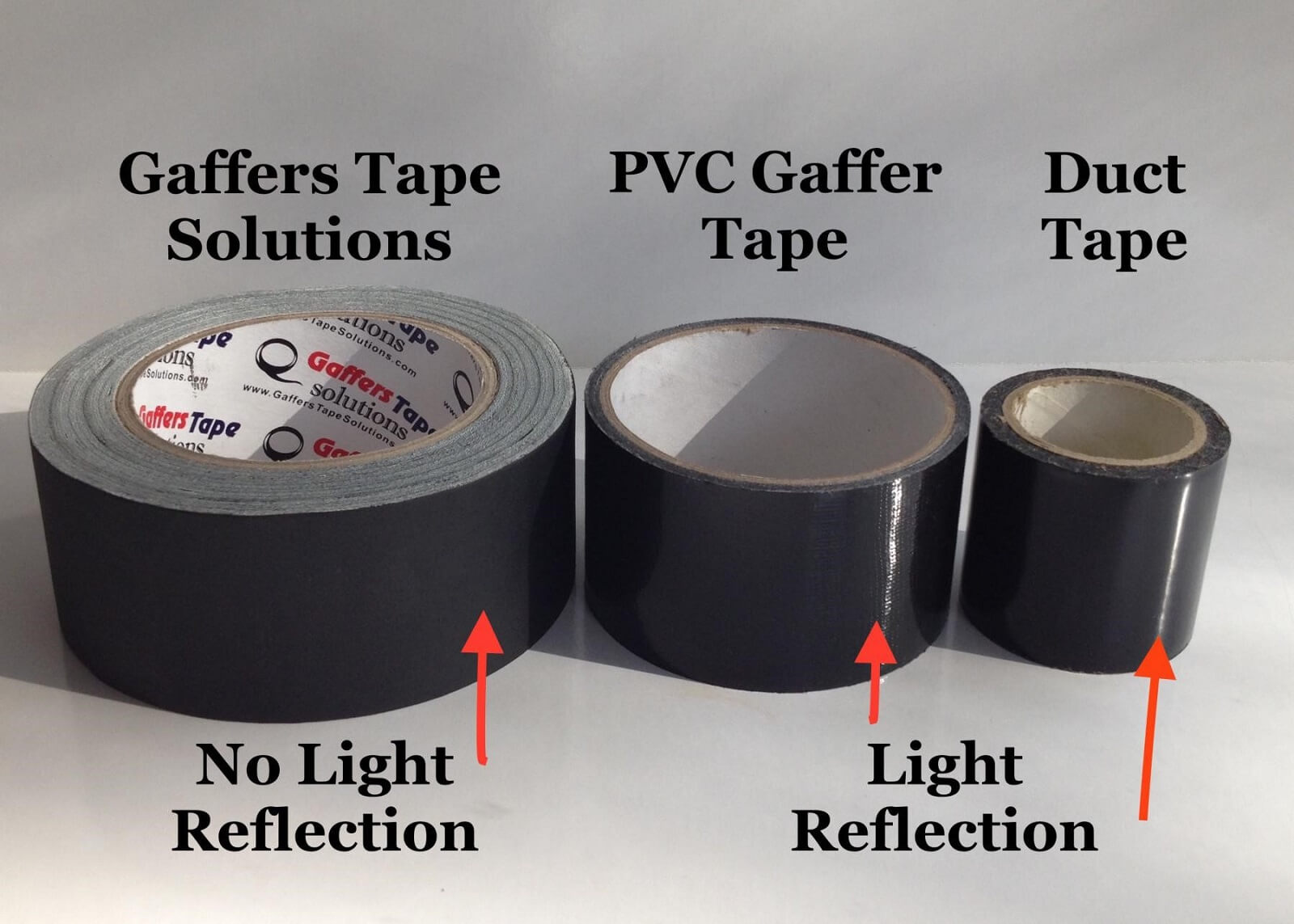

Gaffer tape and electrical tape differ in composition and material. Gaffer tape is made of cotton fabric and coated with a rubber-based adhesive. It offers high tensile strength and can be torn by hand. Electrical tape, on the other hand, is typically made of vinyl and has a pressure-sensitive rubber-based adhesive. It is designed to be stretchy and provide excellent insulation properties.

| Materials Used in Gaffer Tape | Materials Used in Electrical Tape |

|---|---|

| Gaffer tape is made of cotton fabric | Electrical tape is typically made of vinyl |

| Coated with a rubber-based adhesive | Has a pressure-sensitive rubber-based adhesive |

| Offers high tensile strength | Designed to be stretchy |

| Can be torn by hand | Provides excellent insulation properties |

Adhesive Properties Compared

Gaffer tape and electrical tape both have strong adhesive properties. Gaffer tape is known for its high strength and durability, making it ideal for securing cables and heavy-duty applications. It leaves minimal residue, making it easy to remove without damaging surfaces. On the other hand, electrical tape offers excellent adhesive strength for electrical insulation and wire bundling. It is designed to withstand various environmental conditions and provides long-lasting durability. However, it may leave adhesive residue over time, especially when exposed to heat. When choosing between the two tapes, consider the specific application and the importance of residue concerns.

Electrical Insulation Capabilities

Electrical tape is specifically designed to provide insulation in electrical applications. It has excellent insulating properties, preventing the flow of electricity and protecting the user from electric shock. The tape’s insulating capabilities are due to its composition, which typically includes a base material like vinyl or rubber and an adhesive layer.

When wrapped around wires or cables, electrical tape forms a protective barrier that helps prevent short circuits or electrical faults. It is also resistant to heat, moisture, and chemicals, ensuring long-lasting insulation in various environments. Additionally, electrical tape is flexible and easy to work with, allowing for seamless wrapping around irregularly shaped objects.

In contrast, gaffer tape, while versatile in many other applications, does not possess the same level of electrical insulation capabilities. It is not designed or tested for electrical use and may not provide adequate protection against electrical hazards.

Flexibility And Conformability

Gaffer tape is known for its flexibility and ability to conform to various surfaces, making it a favorite for adhering to uneven or irregular textures. Its strong adhesive allows it to stick securely to rough or porous materials.

Electrical tape, on the other hand, is designed for use in tight spaces, making it ideal for wrapping and insulating wires in confined areas where flexibility is key.

Resistance Factors

Gaffer tape and electrical tape differ in resistance factors. Gaffer tape is known for its high resistance to abrasion and water, making it suitable for outdoor use and rough surfaces. On the other hand, electrical tape offers excellent resistance to heat and electricity, making it ideal for electrical insulation and repairs.

Both tapes have distinct resistance properties, catering to different needs and applications.

| Heat and Fire Resistance | Water and Chemical Resistance |

| Gaffer tape offers better heat and fire resistance than electrical tape. | Electrical tape provides superior water and chemical resistance compared to gaffer tape. |

Common Uses In Industry

Gaffer tape and electrical tape are commonly used in different industries. Gaffer tape is preferred for its strong adhesive and residue-free removal, making it ideal for securing cables, while electrical tape is specifically designed to insulate electrical wires and provide protection against moisture and heat.

Both tapes have their own unique applications in various industrial settings.

| Gaffer Tape in Entertainment | Electrical Tape in Electrical Work |

| Used for securing cables and marking stage positions. | Primarily for insulating electrical wires and connections. |

| Residue-free removal without damaging surfaces. | Color-coded for easy identification of wire phases. |

| Water-resistant and can be torn by hand easily. | Offers electrical insulation and protection against voltage. |

Making The Right Choice

When deciding between gaffer tape and electrical tape, it’s crucial to consider the specific application. Gaffer tape is ideal for temporary securing and cable management, while electrical tape is best suited for insulating electrical wires and connections. Each tape serves a distinct purpose, so making the right choice depends on the intended use.

| Gaffer Tape | Electrical Tape |

| Versatile | Insulating properties |

| Leaves no residue | Resistant to weather |

| Strong adhesive | Conforms well to surfaces |

Frequently Asked Questions

What Is The Difference Between Gaffer Tape And Electrical Tape?

Gaffer tape is a strong, cloth-backed tape that is commonly used in the entertainment industry for holding down cables and securing equipment. Electrical tape, on the other hand, is specifically designed for electrical insulation and is commonly used for insulating wires and making repairs.

While both tapes have adhesive properties, they are designed for different purposes.

Can Gaffer Tape Be Used Instead Of Electrical Tape?

While gaffer tape and electrical tape may have similar adhesive properties, they are not interchangeable. Gaffer tape is not designed for electrical insulation and may not provide the same level of protection as electrical tape. It is always best to use the appropriate tape for the specific task to ensure safety and effectiveness.

Which Tape Is More Durable, Gaffer Tape Or Electrical Tape?

Gaffer tape is known for its durability and strength. It is designed to withstand the rigors of the entertainment industry and is often used for securing heavy equipment and cables. Electrical tape, on the other hand, is designed to provide electrical insulation and may not be as durable as gaffer tape.

When it comes to durability, gaffer tape is often the preferred choice.

Can Electrical Tape Be Used Outdoors?

Electrical tape is generally not recommended for outdoor use. It is not designed to withstand exposure to the elements and may deteriorate over time. If you need to make electrical repairs or connections outdoors, it is best to use a weather-resistant tape specifically designed for outdoor use.

Conclusion

After comparing gaffer tape and electrical tape, it is clear that each tape has its own strengths and weaknesses. Gaffer tape offers superior adhesive strength and versatility, making it ideal for a range of applications. On the other hand, electrical tape is specifically designed for electrical work and offers superior insulation properties.

Ultimately, the choice between gaffer tape and electrical tape will depend on the task at hand. It is important to consider the specific needs of the project before making a decision.