Contact cement and contact adhesive are two terms used interchangeably to refer to the same type of adhesive. Contact cement/adhesive is a strong bonding agent that creates an instant, permanent bond when two surfaces are joined together.

Contact cement/adhesive is commonly used in various applications such as woodworking, laminate countertops, and automotive repairs. It is known for its quick-drying properties and high bond strength. Both contact cement and contact adhesive are versatile adhesives that provide strong and durable bonds, making them essential tools for DIY projects and professional applications alike.

Understanding the differences between the two can help you choose the right adhesive for your specific project needs.

Introduction To Contact Cement And Adhesive

Contact cement and adhesive are two terms that often get used interchangeably, but they are actually two different things. Contact cement is a type of adhesive that is applied to both surfaces that need to be bonded together. Once the adhesive dries, the two surfaces are joined together with a strong, permanent bond. Contact adhesive, on the other hand, is a type of glue that is applied to only one surface and allowed to dry. Once it’s dry, the two surfaces are pressed together to form a bond.

| Contact Cement | Contact Adhesive |

|---|---|

| Applied to both surfaces | Applied to only one surface |

| Strong, permanent bond | Forms a strong bond once pressed together |

| Used for large surfaces and heavy materials | Used for small surfaces and lighter materials |

It’s important to understand the differences between contact cement and adhesive, as they each have their own unique properties and uses. Contact cement is often used for large surfaces and heavy materials, while contact adhesive is more commonly used for small surfaces and lighter materials.

Chemical Composition And Properties

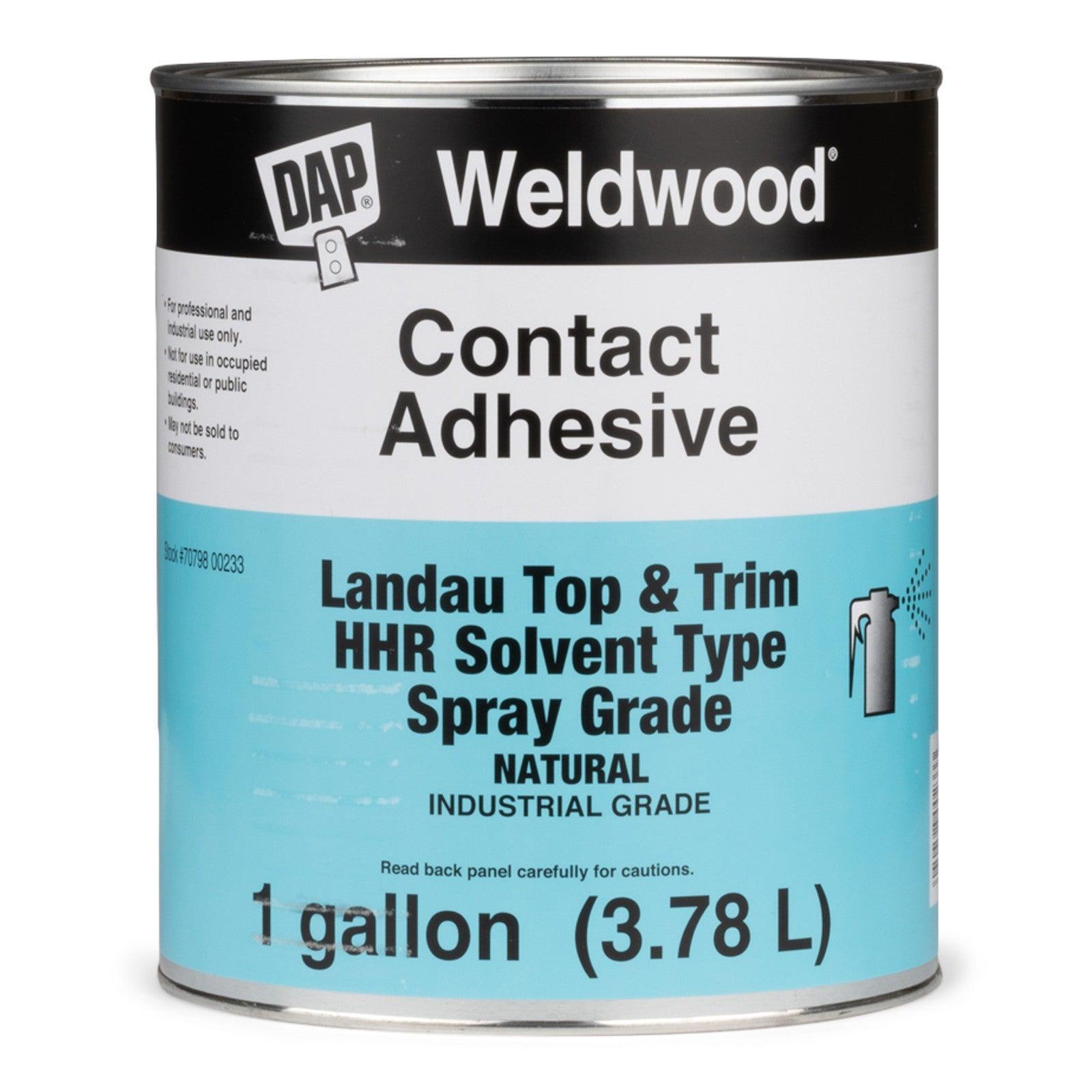

Contact cement and contact adhesive have different chemical compositions and properties. Contact cement contains solvent-based ingredients, such as neoprene, and has a strong, fast-drying formula. On the other hand, contact adhesive is water-based and contains synthetic rubber compounds, offering a flexible bond. The key ingredients in contact cement include toluene and acetone, which provide quick adhesion, while contact adhesive includes vinyl acetate and ethylene vinyl acetate for a more gradual bonding process.

Application Techniques

In order to achieve the best results when using contact cement or contact adhesive, it is important to follow some best practices. Firstly, make sure to clean and prepare the surfaces that will be bonded. Remove any dust, dirt, or grease using a suitable cleaner. Next, apply a thin and even layer of adhesive to both surfaces using a brush or roller. Allow the adhesive to dry partially before joining the surfaces together. This will create a tacky surface that will help with bonding. Press the surfaces firmly together, ensuring even contact across the entire area. It is also recommended to use clamps or weights to hold the surfaces in place while the adhesive fully cures. Finally, allow sufficient time for the adhesive to cure according to the manufacturer’s instructions before subjecting the bonded surfaces to any stress or load.

Curing Times And Conditions

Contact cement and contact adhesive have different curing times and conditions. While contact cement requires pressure and immediate bonding, contact adhesive allows for repositioning and longer curing times. It’s important to consider the specific application and desired outcome when choosing between the two.

| Curing Process for Contact Cement | Curing Process for Contact Adhesive |

| Contact cement requires pressure to ensure proper adhesion. It must be clamped or weighted for about 1-2 hours. It cures fully in 24 hours. | Contact adhesive needs time to set firmly. After application, it should be left for 15-30 minutes before joining the surfaces. Complete curing usually takes 72 hours. |

Bond Strength And Durability

Contact cement and contact adhesive both offer strong bond strength and durability. Contact cement typically provides a stronger bond initially, while contact adhesive may offer better long-term durability. When comparing bond strength, it’s important to consider the specific materials being bonded. Contact cement is often preferred for bonding non-porous materials such as plastic or laminates, while contact adhesive is suitable for porous materials like wood or fabric. The longevity of the materials being bonded is also a crucial factor. Contact cement may provide a more permanent bond, whereas contact adhesive can be more flexible, allowing for natural movements of the bonded materials over time.

Versatility And Material Compatibility

Contact cement and contact adhesive offer versatility and material compatibility for various projects. While contact cement provides strong, immediate adhesion for non-porous materials, contact adhesive offers flexibility and bonding for porous and non-porous surfaces, making it ideal for a wide range of applications.

| Contact Cement | Contact Adhesive |

| Best for large surface areas. | Great for quick fixes and small projects. |

| Works well with wood, metal, and plastic. | Ideal for paper, cardboard, and fabrics. |

Safety And Environmental Considerations

Considering safety and environmental factors, contact cement and contact adhesive both have their advantages and disadvantages. While contact cement is highly flammable and can release harmful fumes, contact adhesive is less toxic and easier to clean up. It’s important to carefully weigh the pros and cons before selecting the appropriate adhesive for your project.

| Safety and Environmental Considerations |

| Health Precautions While Using Contact Cement |

| Environmental Impact of Contact Adhesives |

Cost Analysis And Availability

Contact cement and contact adhesive are two popular options for bonding materials, but they differ in terms of cost and availability. While contact cement is widely available and relatively inexpensive, contact adhesive tends to be pricier and may have limited availability.

Consider your budget and the project requirements when choosing between the two.

| Contact Cement | Contact Adhesive |

| Affordable | Slightly more expensive |

| Widely available | Varies in availability |

| Ideal for large projects | Great for small projects |

Real-world Applications

Contact cement and contact adhesive are two types of adhesives commonly used in real-world applications. While they both provide strong and permanent bonds, contact cement is ideal for bonding non-porous materials such as plastic and metal, while contact adhesive is suitable for porous surfaces like wood and fabric.

| Contact Cement | Contact Adhesive |

| Strong bond | Flexible bond |

| Used for wood, metal, plastic | Works on porous and non-porous surfaces |

| Quick drying time | Longer drying time |

Expert Opinions And Industry Preferences

Experts in the industry often recommend using contact cement over contact adhesive for stronger and more durable bonds. Contact cement offers a reliable and long-lasting adhesion, making it a preferred choice for various applications. Its versatility and effectiveness make it a top choice among professionals.

| Contact Cement | Contact Adhesive |

| High initial tack | Flexible bond |

| Waterproof | Heat resistant |

| Non-flammable | Good for porous surfaces |

| Good for large surface areas | Good for vertical applications |

Conclusion And Recommendations

In conclusion, both contact cement and contact adhesive have their own strengths and weaknesses. Contact cement is known for its strong bond and resistance to heat and moisture, making it ideal for heavy-duty applications. On the other hand, contact adhesive offers more flexibility and is easier to work with on uneven surfaces. When selecting an adhesive, consider the specific requirements of your project and choose the one that best suits your needs. Moreover, keep an eye on future developments in adhesive technology, as advancements may offer even better solutions for various bonding needs.

Frequently Asked Questions

What Is The Difference Between Contact Cement And Contact Adhesive?

Contact cement and contact adhesive are terms often used interchangeably, but they refer to the same type of adhesive. Both are strong, fast-drying adhesives that create a strong bond between two surfaces. The main difference lies in their composition, with contact cement being solvent-based and contact adhesive being water-based.

This difference affects their application and drying time.

Can Contact Cement And Contact Adhesive Be Used On The Same Materials?

Yes, both contact cement and contact adhesive can be used on the same materials. They are commonly used for bonding materials such as wood, metal, plastic, and laminates. However, it’s important to choose the appropriate adhesive based on the specific requirements of the project and the materials being bonded.

Which Adhesive Is Better For Large Surface Areas?

When working with large surface areas, contact cement is often the preferred choice. Its strong bond and quick drying time make it suitable for larger projects. However, contact adhesive can also be used for larger surfaces, especially when a water-based adhesive is preferred or when working with materials that may be sensitive to solvent-based adhesives.

It’s important to consider the specific needs of the project when choosing between the two.

Are There Any Safety Precautions To Consider When Using Contact Cement Or Contact Adhesive?

Yes, safety precautions should always be followed when using contact cement or contact adhesive. Both adhesives contain volatile compounds that can be harmful if inhaled or come into contact with the skin or eyes. It’s important to work in a well-ventilated area, wear protective gloves and goggles, and avoid prolonged exposure to the fumes.

Additionally, these adhesives should be stored in a cool, dry place and kept out of reach of children.

Conclusion

Both contact cement and contact adhesive have their own unique properties and applications. Choosing the right one depends on the specific project and materials involved. It’s important to carefully read the labels and instructions before use to ensure proper application and safety precautions.

By understanding the differences and advantages of each, you can make an informed decision and achieve a successful outcome for your project.