J-B Weld is ideal for heavy-duty bonding, while super glue is best for quick fixes. When deciding between J-B Weld and super glue for your project, consider the materials being bonded and the strength required.

Both have their strengths and weaknesses, so understanding the differences is crucial. J-B Weld is a two-part epoxy that forms a strong bond on various surfaces, making it suitable for metal, wood, plastic, and more. On the other hand, super glue is a fast-acting adhesive that works best on non-porous materials like glass, ceramics, and certain plastics.

By knowing the distinctions between J-B Weld and super glue, you can choose the right adhesive for your specific needs.

Introduction To The Adhesive Titans

When it comes to bonding materials, two of the most popular options are Jb Weld and Super Glue. While both are adhesives, they have distinct differences in their properties and uses.

Jb Weld’s Unique Properties

Jb Weld is a two-part epoxy that creates a strong, permanent bond when mixed together. It has the ability to fill gaps and can be used on a variety of surfaces, including metals, plastics, and ceramics. Jb Weld also has a high tolerance for heat, making it ideal for use in automotive repairs.

Super Glue’s Fast-acting Formula

Super Glue, on the other hand, is a fast-acting adhesive that forms an instant bond. It is best used for small repairs and bonding non-porous materials, such as glass and metal. However, it is not recommended for use on flexible materials or items that will be exposed to high temperatures.

| Adhesive | Properties | Uses |

|---|---|---|

| Jb Weld | Two-part epoxy, fills gaps, heat-resistant | Automotive repairs, bonding metals, plastics, ceramics |

| Super Glue | Fast-acting, instant bond | Bonding non-porous materials, small repairs |

Chemical Composition And How It Affects Performance

The chemical composition of Jb Weld and Super Glue directly influences their performance and bonding strength. Jb Weld, with its two-part epoxy formula, offers superior durability and versatility compared to the quick-drying nature of Super Glue, making it ideal for heavy-duty applications.

| Chemical Composition and How It Affects Performance | |

| The Science Behind Jb Weld | The Jb Weld’s compound includes epoxy resin and hardener. When combined, they form a strong and durable bond, especially on metal surfaces. The chemical reaction creates a heat-resistant and waterproof seal. |

| The Formula of Super Glue | Super Glue, also known as cyanoacrylate, forms an instant bond when it comes into contact with moisture. Its chemical structure allows for quick curing and strong adhesion, making it ideal for smaller, delicate repairs. |

Application Techniques For Maximum Bond

Preparing Surfaces for Jb Weld:

- Thoroughly clean and dry the surfaces to be bonded.

- Remove any rust, paint, or grease using sandpaper or a degreaser.

- Roughen the surface with sandpaper for better adhesion.

- Apply Jb Weld evenly and press the surfaces together firmly.

- Leave it undisturbed for the recommended curing time.

Best Practices for Applying Super Glue:

- Ensure the surfaces are clean and dry.

- Apply a small amount of super glue to one surface.

- Press the surfaces together and hold firmly for a few seconds.

- Avoid using excessive glue as it may cause messiness or slow curing.

- Allow the bond to set and cure completely.

Curing Time And Durability

Jb Weld’s Bonding Strength Over Time: Jb Weld is known for its remarkable bonding strength that increases over time. Once cured, it forms a permanent bond that withstands extreme conditions and temperatures.

Super Glue’s Quick Fix and Longevity: Super Glue provides a quick adhesive solution for immediate fixes, but its longevity may vary depending on the surface and conditions. It may not be as durable as Jb Weld in certain applications.

Versatility Across Different Materials

J-B Weld and super glue both offer versatility across different materials, making them popular choices for various DIY projects and repairs. Whether it’s metal, wood, plastic, ceramic, or glass, these adhesives provide strong and reliable bonds, catering to a wide range of needs.

| Jb Weld Vs Super Glue |

| Versatility Across Different Materials |

| JB Weld is known for its strong bonding capabilities on metal and plastics. It excels in repairing car parts, plumbing fixtures, and even outdoor equipment. On the other hand, Super Glue is incredibly versatile, adhering to a wide range of materials, including wood, ceramics, and rubber. It’s a go-to adhesive for quick fixes around the house, from mending broken dishes to crafting projects. |

Temperature And Weather Resistance

When it comes to temperature and weather resistance, Jb Weld outperforms super glue. Jb Weld is designed to withstand extreme temperatures and harsh weather conditions, making it a more reliable choice for outdoor or heavy-duty applications. Its superior resistance ensures a long-lasting and durable bond in challenging environments.

| Jb Weld | Super Glue |

| Resistant to high temperatures and harsh weather conditions. | May not withstand extreme temperatures or weather exposure. |

| Provides durable bond that remains strong in outdoor settings. | Performance may weaken in varying environmental elements. |

Safety And Precautions

Safety and precautions should be a top priority when comparing Jb Weld and Super Glue. It is essential to follow the instructions carefully, wear protective gear, and work in a well-ventilated area to minimize any potential risks.

| Safety and Precautions |

| Handle Jb Weld and Super Glue with care to avoid accidents. |

| Wear gloves and protective eyewear when using these adhesives. |

| Ensure proper ventilation in the work area to prevent inhaling fumes. |

| Keep Jb Weld and Super Glue away from children and pets. |

Conclusion: Choosing The Right Adhesive For Your Project

Choosing the right adhesive for your project can make all the difference. When comparing JB Weld and super glue, consider the specific needs of your project. JB Weld offers a strong, durable bond for metal, while super glue provides a quick and easy solution for smaller, lightweight materials.

Make the right choice for a successful outcome.

| Evaluating Project Needs |

| Jb Weld and Super Glue serve different purposes, choose based on material compatibility. |

| Consider the strength required for your project, Jb Weld excels in bonding metals. |

| Super Glue is ideal for quick fixes and non-porous materials like plastic and ceramics. |

| For projects needing long-lasting and durable bonds, Jb Weld is the preferred choice. |

Frequently Asked Questions

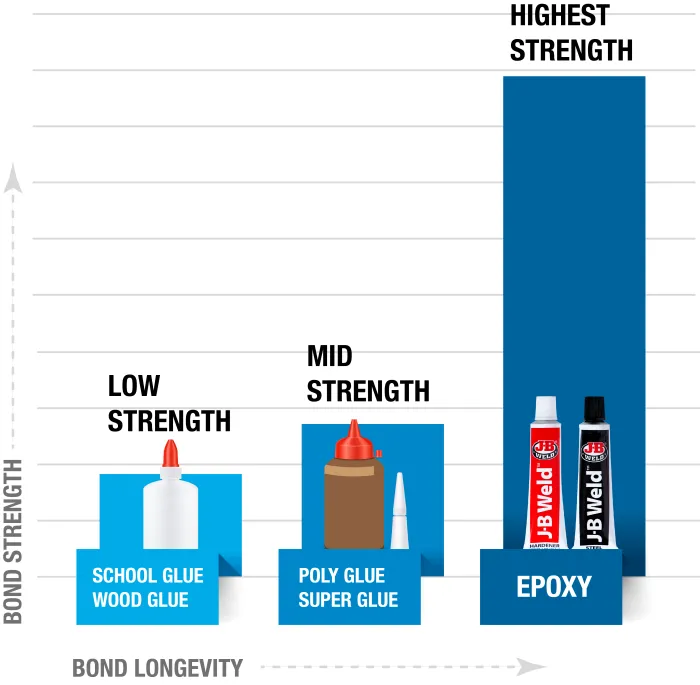

Is Jb Weld Stronger Than Super Glue?

JB Weld is stronger than Super Glue. JB Weld is an epoxy adhesive that can withstand high temperatures, pressure, and chemical resistance, making it perfect for heavy-duty repairs. Super Glue, on the other hand, is a cyanoacrylate adhesive that is suitable for light-duty repairs.

Can Jb Weld Be Used On Plastic?

Yes, JB Weld can be used on plastic. However, it’s important to note that different types of plastic require different types of adhesives. JB Weld has a plastic bonder that is specifically designed to bond plastic surfaces, making it perfect for plastic repairs.

Can Super Glue Be Used On Metal?

Yes, Super Glue can be used on metal. However, it’s important to note that Super Glue is not suitable for heavy-duty metal repairs. It’s best used for small, non-load-bearing repairs where a quick bond is needed.

Which One Is Better For Automotive Repairs, Jb Weld Or Super Glue?

JB Weld is better for automotive repairs than Super Glue. JB Weld is a two-part epoxy that is specifically designed for heavy-duty repairs, making it perfect for automotive repairs. Super Glue, on the other hand, is not suitable for heavy-duty repairs and is best used for small, non-load-bearing repairs.

Conclusion

Both J-B Weld and Super Glue have their own unique properties and applications. J-B Weld is a versatile epoxy adhesive that is known for its strength and durability, making it ideal for heavy-duty repairs. On the other hand, Super Glue is a fast-acting cyanoacrylate adhesive that is great for quick fixes and bonding small objects.

Ultimately, the choice between the two depends on the specific project requirements. Remember to consider factors such as materials, strength needed, and drying time before making your decision. Happy repairing!