J-B Weld works by combining two components to create a strong and durable bond. The two-part epoxy mixture chemically reacts to form a powerful adhesive.

This versatile product can be used for various applications, including metal, wood, plastic, and more. J-B Weld is known for its quick-setting properties and high bond strength, making it a popular choice for DIY enthusiasts and professionals alike. Whether you need to fix a broken tool or create a new project, J-B Weld provides a reliable solution that is easy to use and long-lasting.

Introduction To Jb Weld

JB Weld is a type of epoxy adhesive that is popular for its strength and versatility. The adhesive is made up of two parts: a resin and a hardener. When mixed together in equal parts, the resin and hardener create a chemical reaction that forms a bond that is stronger than the sum of its parts.

The origins of JB Weld date back to the 1960s, when it was first created as a solution for repairing damaged metal parts. Since then, the product has evolved and is now used to bond a wide range of materials including metal, wood, plastic, and ceramics.

| What Sets JB Weld Apart |

|---|

| – Creates a strong bond that can withstand high pressure and temperatures |

| – Can be used on a variety of materials |

| – Easy to use with a simple mixing process |

| – Dries quickly for fast repairs |

Chemistry Behind Jb Weld

The chemistry behind JB Weld is fascinating. The key ingredients in JB Weld are the epoxy resin and the hardener. When combined, these two substances create a strong bond that can withstand high temperatures and extreme pressure. The epoxy resin acts as the adhesive, bonding the materials together, while the hardener initiates the curing process. Once mixed, the two components undergo a chemical reaction, forming strong cross-links that provide exceptional strength and durability. This dynamic duo ensures that JB Weld is a reliable and long-lasting solution for various repairs.

The Science Of Adhesion

The science of adhesion is fascinating. Jb Weld works by forming strong bonds at the molecular level. When joining two surfaces, it’s crucial to prepare them properly for optimal adhesion. This involves cleaning the surfaces thoroughly and roughening them up to create a better grip for the epoxy. Once the surfaces are prepared, Jb Weld can effectively bond a wide range of materials, including metal, wood, and plastic. This versatility makes it a popular choice for DIY repairs and projects. Understanding how Jb Weld works at the molecular level can help users achieve the best results when using this powerful adhesive.

Applications Of Jb Weld

JB Weld is a versatile adhesive that can be used for a wide range of applications. From automotive repairs to household fixes, JB Weld provides a strong and durable bond that can withstand extreme conditions. Whether you need to fix a cracked engine block, repair a leaking pipe, or mend a broken tool, JB Weld can get the job done.

One of the unique projects where JB Weld can be used is in arts and crafts. It can be used to create sculptures, jewelry, and even decorative household items. Its strong adhesive properties make it perfect for bonding different materials together, such as metal, wood, plastic, and ceramics.

Another interesting application is in plumbing repairs. JB Weld can effectively seal leaks in pipes and fittings, providing a long-lasting solution. It can also be used to fix leaks in radiators, water tanks, and other plumbing fixtures.

In conclusion, JB Weld is a reliable and versatile adhesive that can be used for various applications, from automotive repairs to household fixes. Its strong bonding properties make it a go-to solution for many unique projects.

Mixing And Applying Jb Weld

JB Weld is a two-part epoxy adhesive that consists of a resin and a hardener. When the two parts are mixed together, a chemical reaction occurs, creating a strong and durable bond. To mix JB Weld, squeeze out equal amounts of the resin and hardener and thoroughly blend them together. Apply the mixture to the surface, ensuring that it is clean and free of grease or oil. Press the parts together firmly and hold them in place for a few minutes to allow the bond to set. For a strong and lasting bond, it’s important to follow the manufacturer’s instructions carefully and to allow sufficient time for the adhesive to cure. Following these steps will ensure that your repair or project is completed successfully.

Curing Process Of Jb Weld

JB Weld works by utilizing a two-part epoxy resin that, when mixed, creates a strong bond. During the curing process, the epoxy hardens to form a durable seal that can withstand high temperatures and pressures, making it ideal for various repair applications.

| How Does Jb Weld Work |

| Curing Process of JB Weld |

| Understanding Cure Times |

| Factors Affecting the Curing Process |

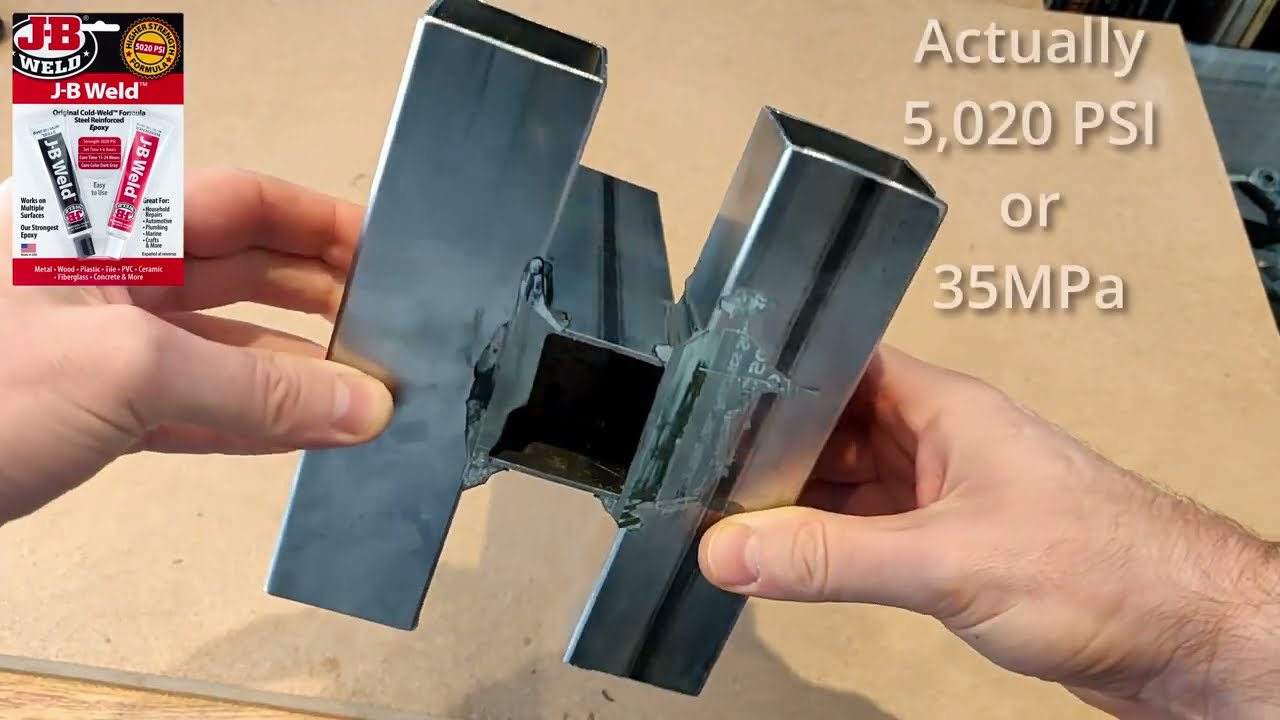

Strength And Durability Tests

J-B Weld’s strength and durability are tested through rigorous trials to ensure its reliability in bonding materials. The unique formula creates a strong and lasting bond, making it a popular choice for various repair and DIY projects. Its effectiveness lies in the combination of strength and durability, providing long-lasting results.

| How Does Jb Weld Work |

| Strength and Durability Tests |

| Comparing JB Weld to Other Adhesives |

Safety And Precautions

J-B Weld is a reliable and effective solution for various repairs. Its unique formula combines two parts to create a strong bond that can withstand extreme conditions. By following the safety precautions provided, users can ensure a successful and secure application.

| Safety and Precautions |

| Handle JB Weld with care to prevent skin and eye contact. |

| Avoid inhalation of vapors; use in well-ventilated areas. |

| Dispose of unused JB Weld responsibly according to local regulations. |

| Consider environmental impact when discarding JB Weld waste. |

Frequently Asked Questions

How Does Jb Weld Work?

Jb Weld is a two-part epoxy adhesive that works by combining resin and hardener to create a strong bond. When mixed together, the two components chemically react and create a durable adhesive that can bond various materials, including metal, plastic, wood, and more.

Jb Weld cures in about 4-6 hours and reaches its full strength in 24 hours.

Can Jb Weld Be Used On Plastic?

Yes, Jb Weld can be used on plastic. It is specially formulated to bond a wide range of materials, including plastic. However, it is important to clean the plastic surface thoroughly before applying Jb Weld to ensure proper adhesion. Additionally, it is recommended to roughen the plastic surface for better bonding results.

Is Jb Weld Waterproof?

Yes, Jb Weld is waterproof once it has fully cured. It can withstand exposure to water, including immersion, without losing its adhesive properties. This makes it suitable for various applications, such as repairing leaks in plumbing systems or fixing outdoor equipment that may come into contact with water.

How Long Does It Take For Jb Weld To Dry?

Jb Weld typically takes around 4-6 hours to dry and reach a tack-free state. However, it is important to note that curing time may vary depending on factors such as temperature, humidity, and the thickness of the applied Jb Weld.

For maximum strength, it is recommended to allow 24 hours for Jb Weld to fully cure.

Conclusion

J-B Weld is a versatile adhesive that can be used for various purposes. It works by creating a strong bond between the surfaces, filling gaps, and hardening to form a permanent seal. The two-part epoxy system is easy to use and can be applied to a wide range of materials.

Whether you need to fix a broken tool or repair a leaky pipe, J-B Weld can provide a reliable solution. With its impressive strength and durability, this adhesive has become a go-to choice for many DIY enthusiasts and professionals. So, if you’re looking for a reliable adhesive, J-B Weld is definitely worth considering.